Description

Near Dry Machining

Type: Medium paste (blue)

Size: 4 oz jar

BOELUBE ia a Boeing developed lubricant, it fights friction at the interface of the cutting edge and the workpiece. The reduction of friction at these surfaces minimizes heat generation and concurrent chip weld. Tools retain their cutting edge longer, leading to closer tolerances and prime chip yield.

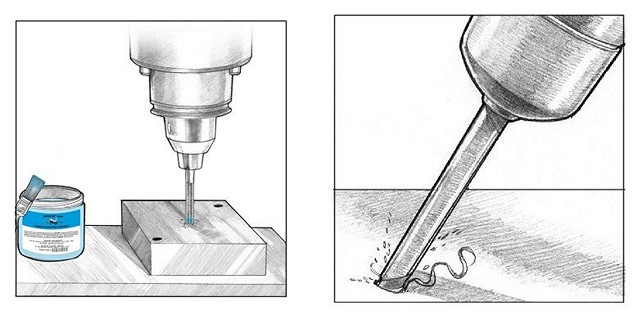

BOELUBE is an extremely cost effective solution for single point work such as drilling and reaming, it improves tool life by reducing heat build-up by applying BOELUBE to the tool before start-up.

In near dry machining the goal is high efficiency, which is achieved as a result of using a minimal quantity of lubricant, this produces near dry work pieces and chips with little or no clean up (or related costs and disposal costs).

Drilling is one of the most widely used machining processes to produce circular holes in metallic and non metallic materials, and is generally characterized as a roughing process (rough form), whereas reaming is considered a finishing process (exact form).

BOELUBE come in a variety of shapes and sizes to accommodate ease of application in drilling, tapping, reaming, abrasive belts, deburring, grinding wheels, band, circular and hand saw blades.

Typically BOELUBE solid is applied to the tool before start-up, in a block or tube form, it can be hand held and a drill bit can be touched to the solid before drilling or the solid may be swiped across the surface to be drilled. Only a minimal amount is required when drilling through thin material.

Major Benefits of BOELUBE:

– when forming or bending it provides an excellent means of obtaining maximum stretch area and close tolerance bends by providing superior lubrication that allows the work piece to attain the desired shape without creating areas that are stressed.

– is non-corrosive, non-flammable, chemically stable and free of halogens, heavy metals, sulfur, phosphorus, silicone, petroleum or paraffin wax.

– does not contain any ingredients considered a hazardous substance by OSHA, WHMIS, IARC, NTP and state regulatory lists. Refer to material safety data sheets for additional information.

– will not promote dermatitis, provides a high degree of worker safety and presents a safe effective method to machine various types of materials without special handling, fluid recycle or typical disposal issues.

– can be removed from surfaces using isopropyl alcohol, denatured alcohol, MEK or aqueous cleaner.

– has an indefinite shelf life.

– does not need to be removed prior to heat treatment.

– is in most cases compatible with paints and sealants (though it is highly recommended that compatibility is determined prior to use).

– provides superior lubrication when machining or forming the increasingly complex range of materials now being used in aerospace, automotive, engineering and a wide variety of other manufacturing industries.